Overview of FIREWIRE IEEE 1394 Communication Protocol

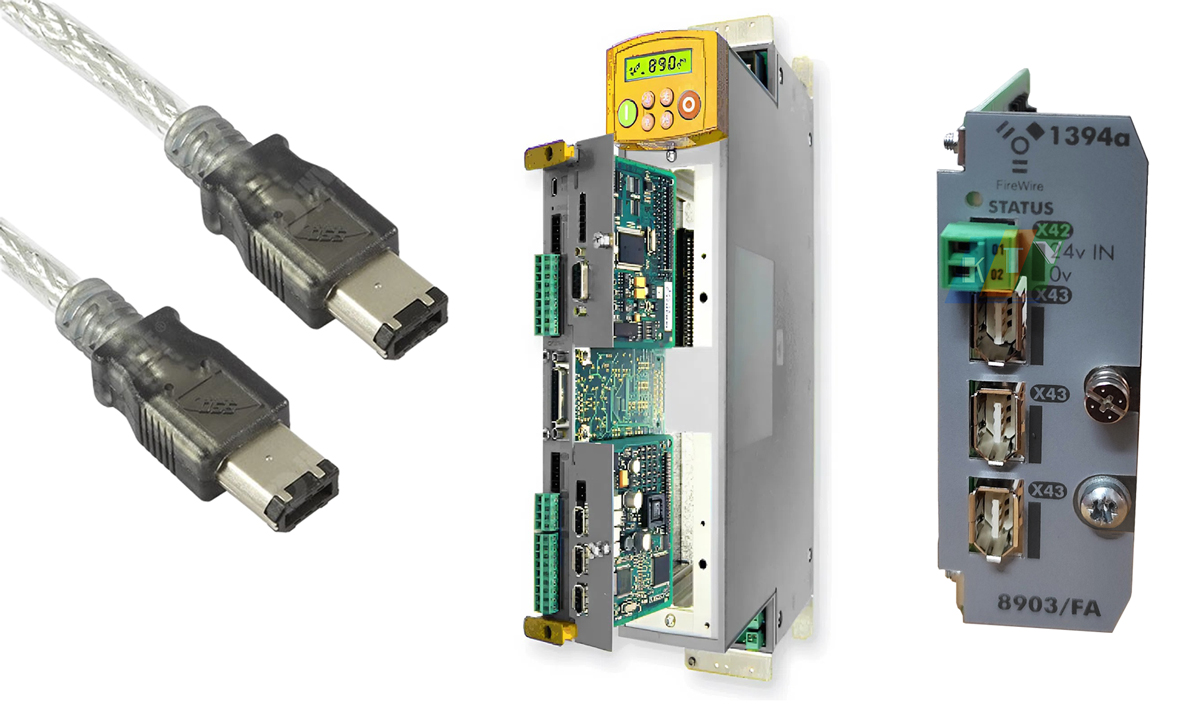

The FireWire communication protocol (IEEE 1394) was primarily used on Parker’s AC890 drive series via the 8903/FA option card.

Main roles of FireWire on AC890:

- Real-time communication: Enables low-latency, high-precision data transfer between multiple servo axes.

- Multi-axis synchronization: AC890 can synchronize multiple axes through FireWire, ideal for printing, packaging, and robotics.

- Reduced wiring: A single FireWire cable can replace multiple individual analog/digital signal lines.

Comparison of FireWire Communication – Pros & Cons

| 🔧 Criterion | ✅ Advantages | ⚠️ Disadvantages |

|---|---|---|

| Data Transmission Speed | High speed, real-time data transfer – suitable for multi-axis motion control. | Less flexibility compared to modern protocols (EtherCAT, Profinet…) |

| Precision & Synchronization | Synchronizes speed, position, torque, and acceleration – ideal for cutting, unwinding, printing. | Relies heavily on software and correct configuration for stable operation. |

| Software Configuration | Integrated within DSE890 software. | Requires licensed software. |

| Hardware Cost | No need for central PLC when only using Parker AC890 drives. | Requires a separate FireWire module (8903-FA-00) → higher cost. |

| Noise Immunity | High-speed digital signal, less affected by industrial noise. | Short cable distance (~4.5m with standard cables), requires high-quality certified cables. |

| System Expandability | Supports daisy-chain and ring topology within limited nodes. | Does not support large networks like Profinet – limited to 6–7 axes. |

| Device Compatibility | Best performance when using complete Parker AC890 system. | Not compatible with third-party drives – proprietary protocol. |

| Upgrade & Replacement | Fully supported by Parker documentation. | FireWire is outdated compared to modern fieldbus (EtherCAT, Profinet…) |

Replacement Solution for FIREWIRE IEEE 1394

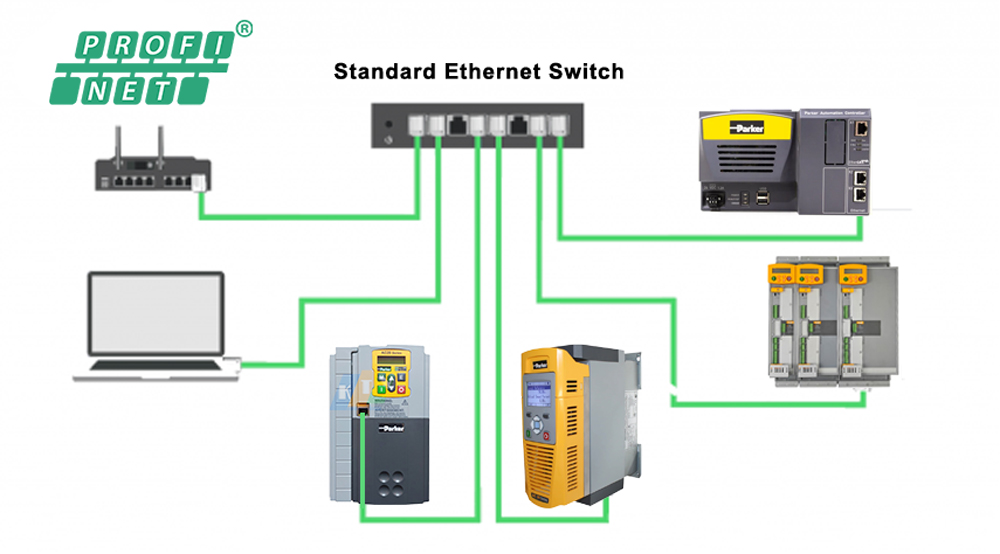

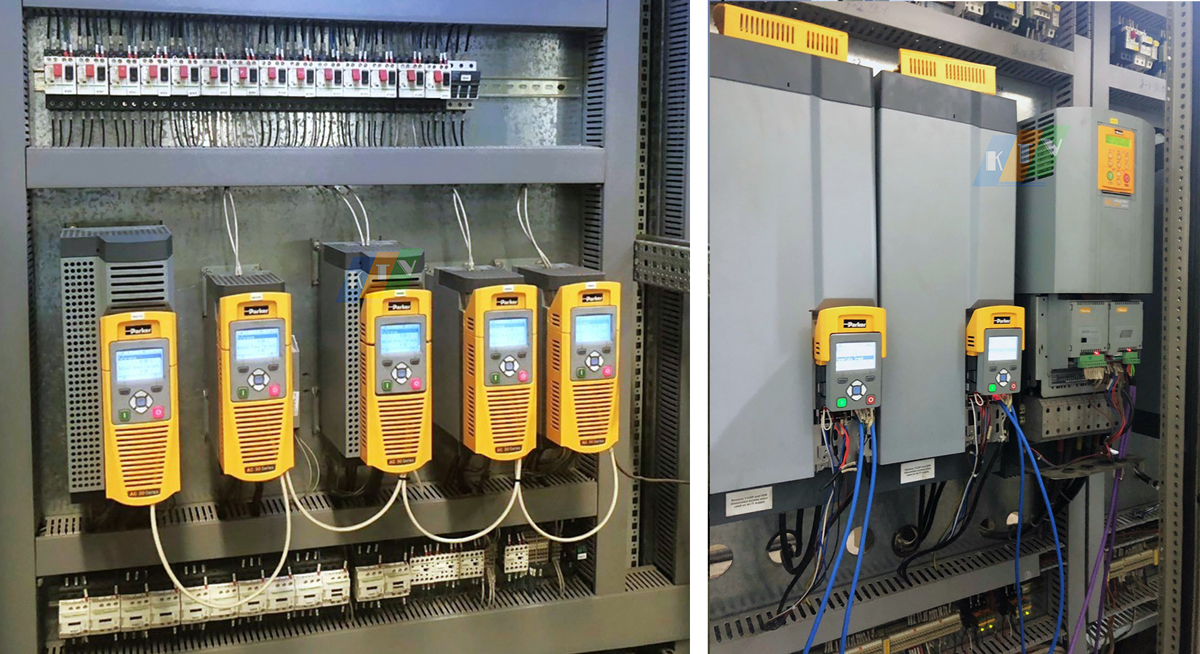

Profinet communication with Parker AC30 drives is a leading alternative to replace FireWire IEEE 1394 used in AC890 systems.

Profinet is a next-generation industrial communication standard developed to extend and modernize Profibus capabilities using Ethernet-based infrastructure. It’s now widely adopted in automation systems, especially with Siemens S7-1200/1500 PLCs, SCADA, and robotics environments.

- Profinet (Process Field Net) is a real-time Ethernet protocol designed for industrial automation.

- Developed by PI (Profibus & Profinet International).

- Uses TCP/IP or UDP/IP over standard Ethernet networks.

- Supports multiple transmission types:

- Real-time (RT) – high-speed control

- Isochronous Real-time (IRT) – for servo or multi-axis synchronization

Integrating Profinet with Parker drives delivers fast data rates, simplified configuration, enhanced monitoring, and meets modern industrial Ethernet standards.

Advantages of Profinet Communication Protocol

| 🔧 Criterion | 💡 Advantages |

|---|---|

| ⚡ Data Speed | – High-speed communication (100 Mbps – Full Duplex). – Suitable for real-time applications and instant speed control. |

| 🔁 I/O Transfer Capability | – Transfer multiple parameters simultaneously (Start/Stop, speed, fault, status…) – Up to 256 bytes I/O |

| 🔗 System Compatibility | – Fully compatible with Siemens PLC, HMI, SCADA… – Widely adopted industrial standard, scalable networking |

| ⚙️ Control Configuration | – Supports control of position, torque, speed, PID quickly and easily |

| 🔍 Maintenance & Monitoring | – Enables status analysis through software like DSElite, PDQ, TIA Portal… |

| 🔌 Physical Connection | – Uses industrial-grade RJ45 Ethernet cable, easy to find and install |

| 💡 Extended Features | – Supports multi-axis synchronization – Includes Safety functions (STO) |