Overview of SSD LINK Communication Protocol

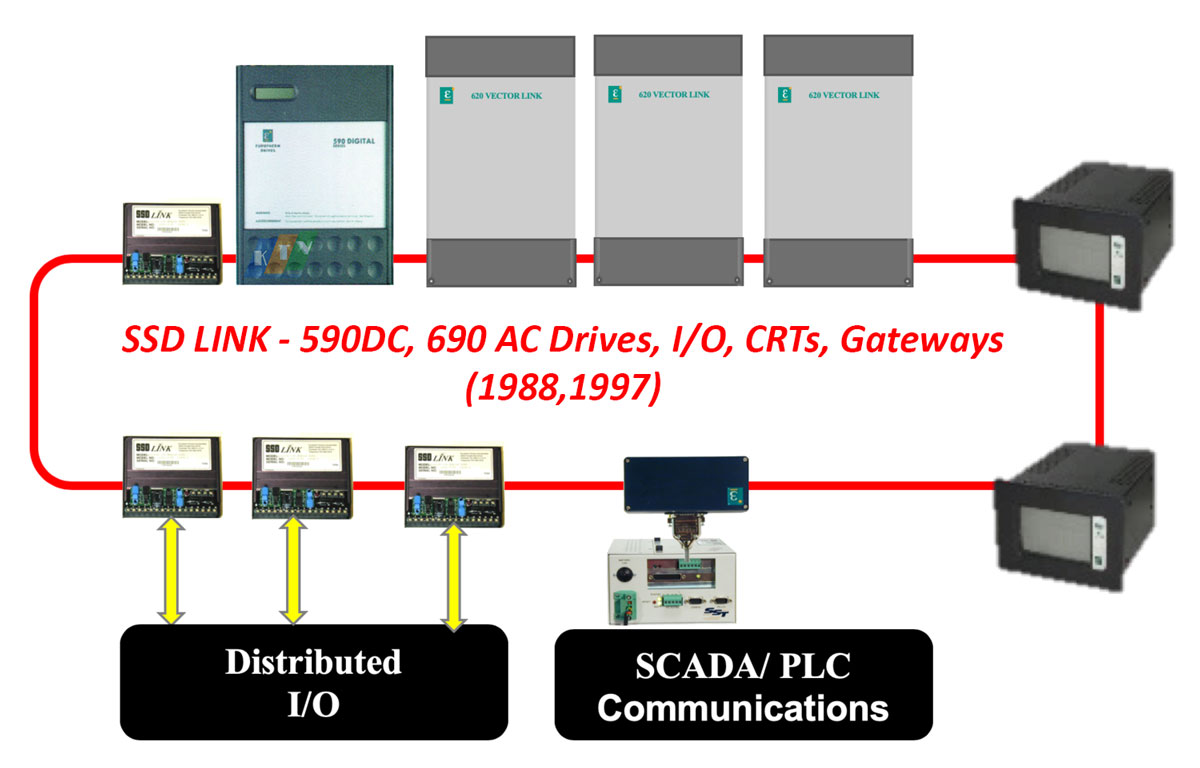

SSD LINK is a distributed control system designed to manage and operate Parker’s DC590 and AC690 motor drives, along with related devices. It is well-suited for process control and various industrial applications. SSD LINK operates on an event-driven mechanism — an event at one module triggers a message to another module, which then responds accordingly.

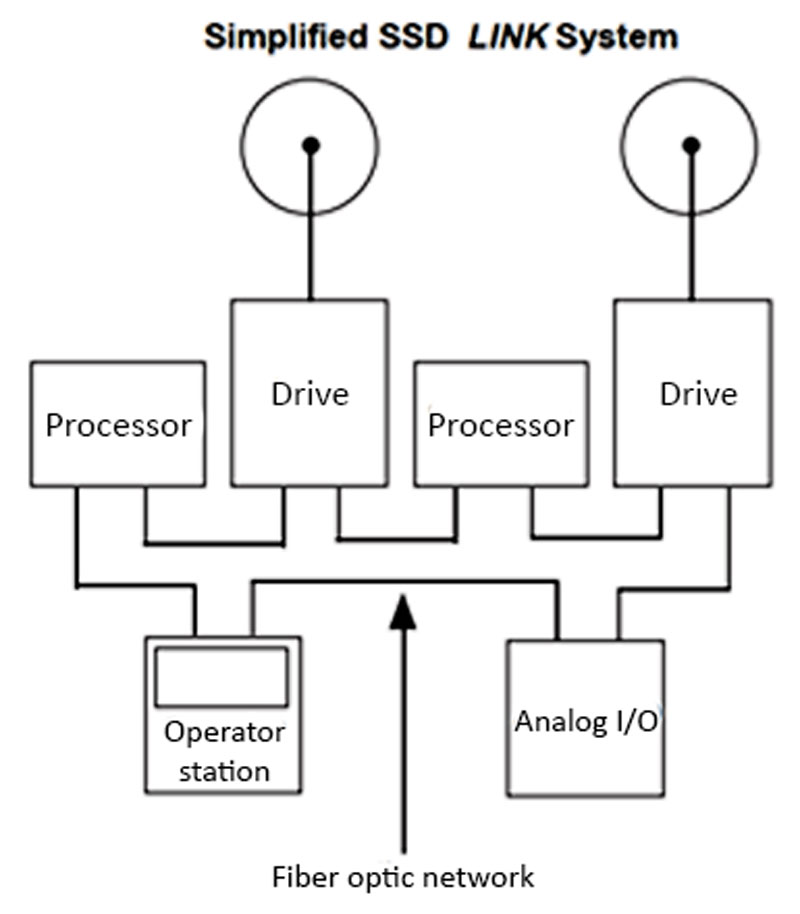

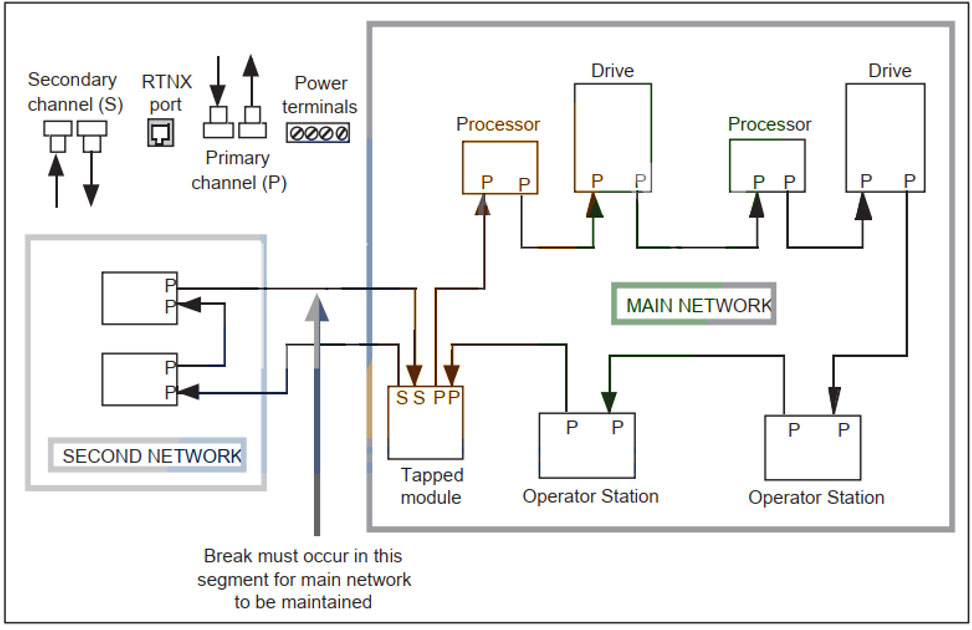

All modules within the SSD LINK system are interconnected via high-speed fiber optic cable, significantly reducing the need for traditional signal and control wiring. The network can be configured in multiple ways to meet application-specific needs.

Main components of the SSD LINK system include:

- Drives: Directly connected to motors for torque and speed control.

- Operator stations: Display operational data and receive user input.

- Analog I/O modules: Interface with analog signals such as dancer potentiometers and E to P converters.

- Digital I/O modules: Interface with digital signals such as pushbuttons, indicators, relays, and PLCs.

- Serial I/O modules: Interface with processors such as temperature controllers, gauges, and PLCs.

- Interface cards: Used for supervisory computers.

- Gateway modules: Provide connections to other plant networks.

- Repeaters: Extend physical network distance (via fiber optic extension).

- Software tools: Used for configuration, operation, and monitoring of the SSD LINK system.

Technical highlights of the SSD LINK network:

- Peer-to-peer communication

- Data transfer speed: 2.7 Mbps

- Network bandwidth: up to 12,000 messages/sec per segment

- Hardware error detection

- Fiber optic fault detection and recovery

- Dual ring fault-tolerant configuration (optional)

New Communication Upgrade Solutions

1. Why upgrade from SSD LINK?

SSD LINK was a cutting-edge technology from 1988 to 2000, particularly for distributed control systems. However, it no longer meets today’s requirements for scalability, speed, real-time control, and Industry 4.0/IoT connectivity.

Comparison: SSD LINK vs. Modern Industrial Protocols

| Criteria | SSD LINK | Modern Standards (Profinet, EtherCAT, Modbus TCP…) |

|---|---|---|

| Protocol Type | Proprietary (Parker/SSD Drives) | Open, international standards |

| Physical Transmission | Fiber optic | Standard Ethernet (RJ45, CAT5/6 cable) |

| Transmission Speed | ~2.7 Mbps | 10/100/1000 Mbps or more |

| Scalability | ~32 devices | Hundreds of devices, cross-platform |

| Real-time Support | Yes, but limited | Strong real-time capability |

| Flexibility | Low – only usable within SSD systems | High – easily integrates with PLC, SCADA, IoT… |

| Development Tools | DSE Lite, DSE890 | Studio 5000, TIA Portal, Codesys,… |

| Maintenance Capability | Difficult, parts not readily available | Easy, widely supported |

| Current Status | Discontinued, limited support | Global industrial standard |

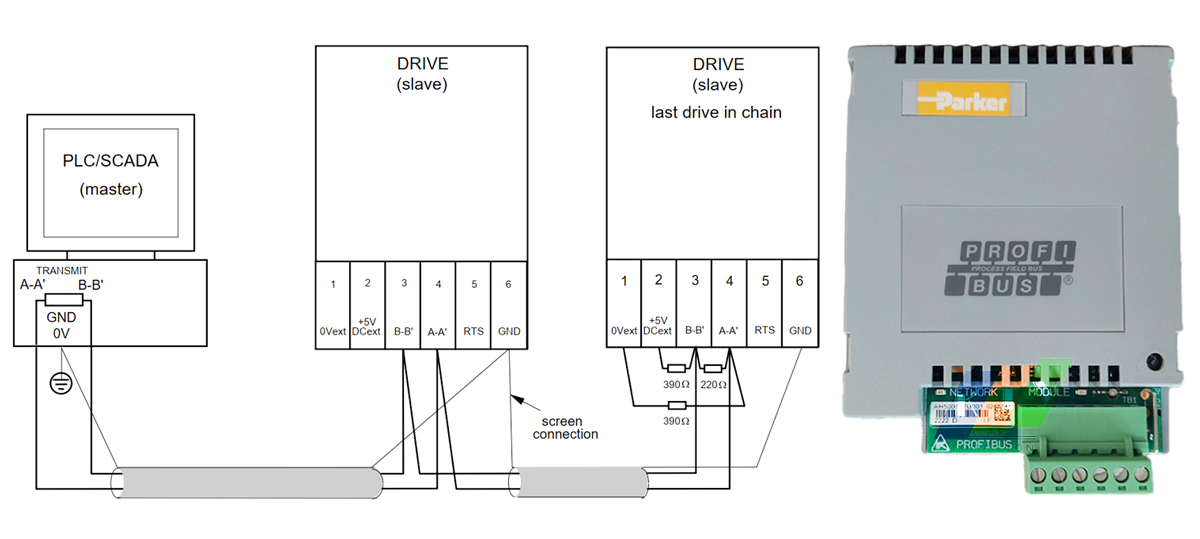

2. Profibus Solution for DC590 Drives

Profibus (Process Field Bus) is the leading solution today for replacing SSD LINK in DC590-based systems.

Profibus Applications in Parker Drive Systems

Required Hardware: Option card 6055-PROF-00

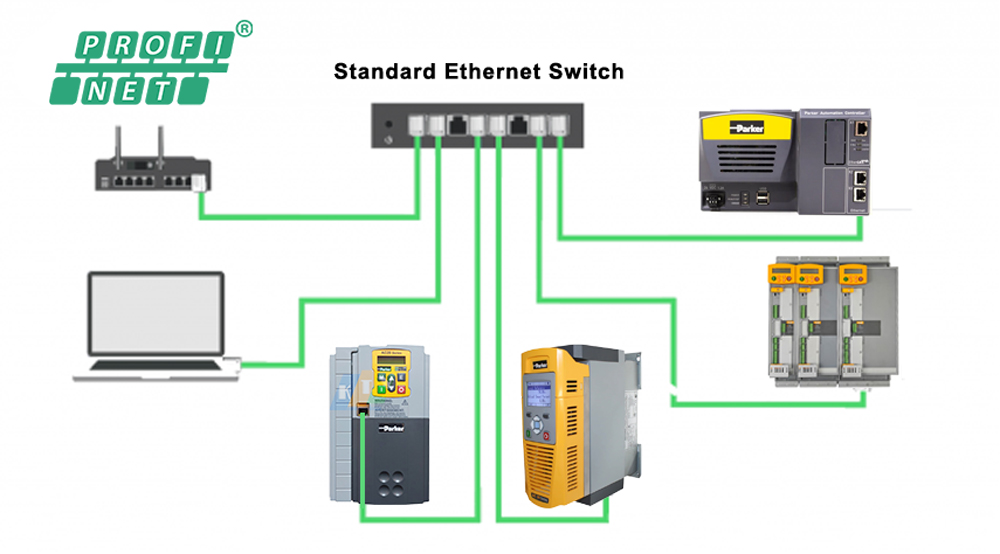

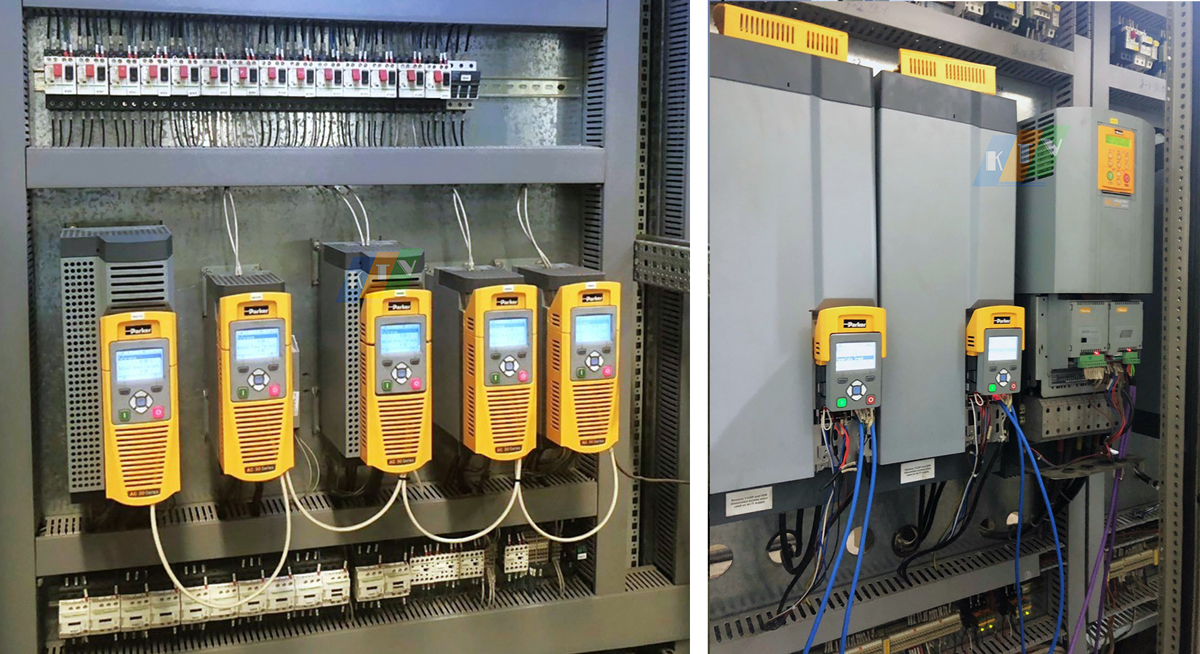

3. Profinet Solution for AC690 Drives

The AC690 drive series has been discontinued and replaced by the AC20 and AC30 drives, depending on the application.

Profinet is the recommended communication protocol to replace SSD LINK in AC690 systems.

Parker’s AC20 and AC30 drives come with built-in Profinet interfaces on the control board — eliminating the need for additional option cards. Profinet integration delivers high-speed communication, simplified configuration, improved diagnostics, and full compatibility with modern industrial Ethernet standards.

Key Advantages of Profinet

| 🔧 Criteria | 💡 Benefits |

|---|---|

| ⚡ Transmission Speed | – High-speed data transmission (100 Mbps – Full Duplex) – Suitable for real-time applications, instant speed control… |

| 🔁 I/O Transmission Capability | – Simultaneous transmission of multiple parameters (Start/Stop, speed, fault, status…) per PLC cycle – Up to 256 byte I/O |

| 🔗 System Compatibility | – Seamless integration with Siemens PLCs, HMIs, SCADA… – Common industry standard, easy to scale |

| ⚙️ Control Configuration | – Capable of controlling position, torque, speed, PID… quickly |

| 🔍 Maintenance & Monitoring | – Monitor and analyze drive status using DSElite, PDQ, TIA Portal… |

| 🔌 Physical Connection | – Uses industrial-grade RJ45 Ethernet cable, easy to source and install |

| 💡 Extended Functionalities | – Supports multi-axis drive synchronization – Supports Safety (STO) |